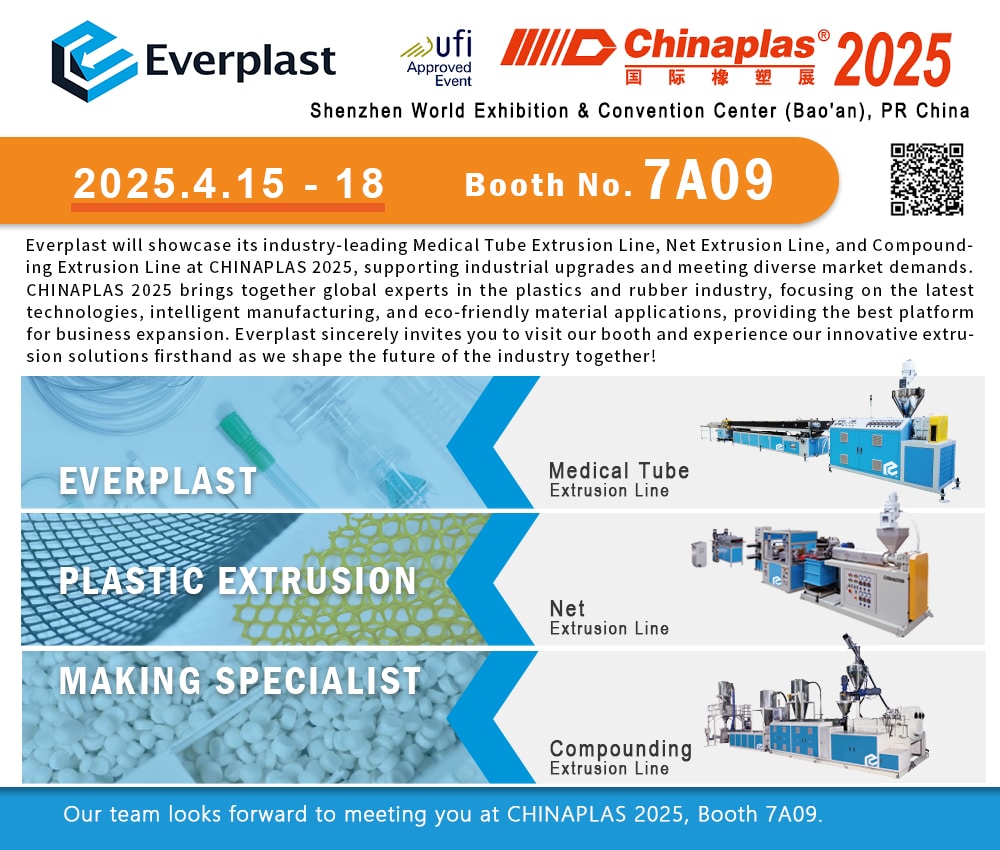

Everplast to Showcase Advanced Medical Tube and Net Extrusion Production Lines at Chinaplas Exhibition – Booth 7A09

Everplast is excited to participate in the upcoming Chinaplas Exhibition, and we sincerely invite industry professionals to visit our Booth 7A09 to explore the latest innovations in plastic extrusion production technology. At this event, we will highlight our medical tube extrusion production line and net extrusion production line, showcasing our expertise in high-precision extrusion technology, material applications, and intelligent manufacturing solutions.

Medical Tube Extrusion Production Line – Precision, Stability, and Efficiency

1. High-Standard Extrusion Equipment for the Medical Industry

Medical-grade plastic tubing plays a crucial role in medical devices and consumables. Everplast has developed a high-precision medical tube extrusion production line that is ideal for manufacturing IV tubes, catheters, oxygen tubes, vascular stents, dialysis tubes, and more.

2. Advanced Technology Ensures Accuracy and Consistency

Our extrusion system is equipped with high-precision extruders, a stable temperature control system, and precision molds to ensure that the produced medical tubes are dimensionally accurate, have uniform wall thickness, and feature a smooth, defect-free surface that meets stringent medical standards. Additionally, our real-time inline measurement technology guarantees that every tube produced conforms to strict specifications.

3. Multi-Layer Coextrusion and Specialized Material Applications

To meet different medical requirements, Everplast’s system supports single-layer, double-layer, and multi-layer coextrusion and is compatible with various medical-grade materials, including PP, PE, PVC, EVA, PU, TPU, FEP, and PFA. Our technology enables the production of tubes with properties such as transparency, anti-fogging, antibacterial surfaces, and high biocompatibility, ensuring product safety and reliability.

4. Intelligent Control System for Enhanced Production Efficiency

Our medical tube extrusion line features a smart HMI (Human-Machine Interface) and PLC automated control system, enabling intuitive operation, precise adjustments, and seamless adaptation to various production specifications. This enhances production flexibility and stability, reducing downtime and increasing output efficiency.

Net Extrusion Production Line – Versatile Design for Wide Applications

1. High-Precision Net Extrusion Technology

Everplast’s net extrusion production line is engineered to manufacture a wide range of plastic net structures, widely used in agricultural protective nets, industrial filtration nets, medical support meshes, construction reinforcement nets, anti-slip mats, and food packaging nets.

2. Advanced Technology for Structural Strength and Flexibility

Our system employs precision mold designs and high-stability extrusion technology, ensuring optimal node strength, uniform mesh size, and consistent structure, producing nets with high strength, durability, and excellent flexibility to meet diverse industrial and consumer needs.

3. Multi-Material Compatibility for Enhanced Product Functionality

Our net extrusion production line supports various thermoplastic materials, such as HDPE, LDPE, PP, EVA, PVC, TPE, and TPU. Additionally, the system can be customized for UV-resistant, antimicrobial, high-flexibility, or weather-resistant formulations, optimizing product performance for specific applications.

4. Automated Production for Maximum Efficiency and Cost Reduction

Equipped with a high-efficiency automation system, Everplast’s net extrusion line features precise extrusion mold design, a stable cooling and forming unit, and an intelligent cutting and winding system. This ensures consistent production quality while minimizing material waste, improving production efficiency, and reducing labor costs.

Why Choose Everplast?

Industry-Leading Technology & Superior Quality

Industry-Leading Technology & Superior Quality

With over 30 years of expertise in plastic extrusion equipment manufacturing, Everplast continuously innovates to ensure the highest standards of quality and reliability.

Customized Solutions for Diverse Market Needs

Customized Solutions for Diverse Market Needs

Our extrusion systems are tailor-made to meet customer requirements, offering the best production solutions for special dimensions, material compatibility, multi-layer coextrusion, and intelligent control systems.

Global Service & Professional Support

Global Service & Professional Support

Everplast provides technical support teams in multiple countries, ensuring customers receive fast and professional after-sales service for smoother production operations and maximum efficiency.

Join Everplast at Booth 7A09 – Chinaplas Exhibition

We look forward to meeting you at the Chinaplas Exhibition! Our technical experts will be on-site to answer your questions and showcase our latest equipment and innovative applications. Whether you’re interested in medical tube extrusion technology or looking for high-efficiency net extrusion production solutions, Everplast has the expertise to support your production needs!

Contact us now to schedule a consultation and discover how Everplast can be your best extrusion equipment partner!

Exhibition Details

Contact us If you want to visit our booth.