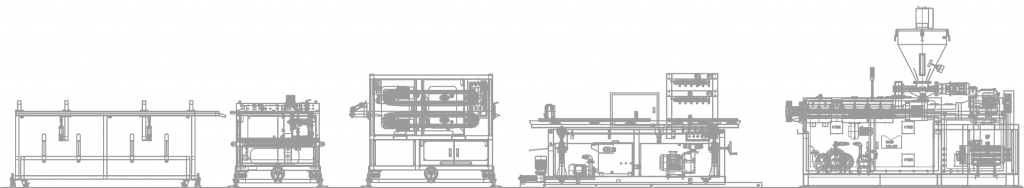

Trunking

machine line

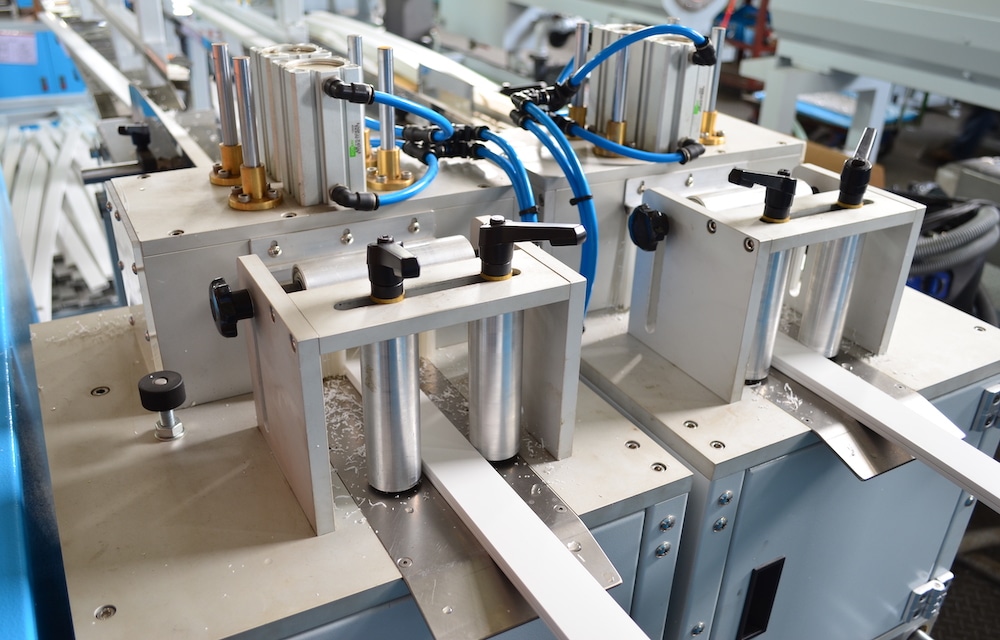

Although the co-extrusion trunking machine line can significantly increase the speed of the product line, its degree of formation is more difficult than the traditional extrusion machine line. For example, the raw materials, types, and sizes of the finished products will affect the co-extrusion machine line feasibility, so it is necessary to have a stable precision mold and better machine performance.

1/4 of the R&D design team is the powerhouse of Everplast. Given the opportunity of multiple investment research and development plans, cross-industry cooperation, and obtaining several patents, we can anticipate the needs of customers to provide exceptional customer services.

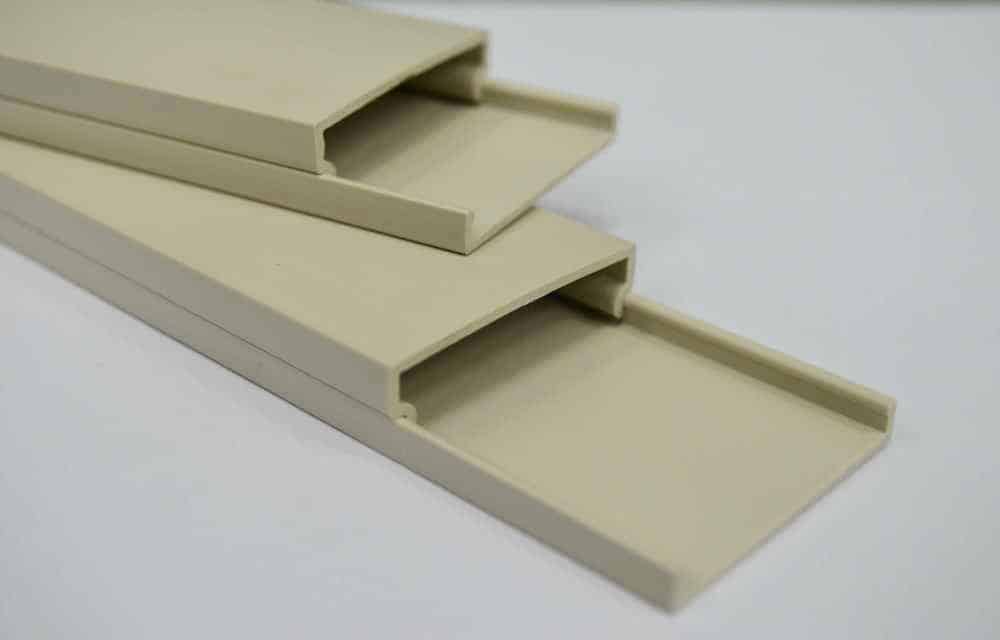

The finished product size of the trunking ranges from 15mmx9mm to 100mmx100mm. It is widely used to organize power cables, data cables, and other wires to prevent leakage. In addition, the finished product is non-conductive and fire resistant.

APPLICATION

FEATURES

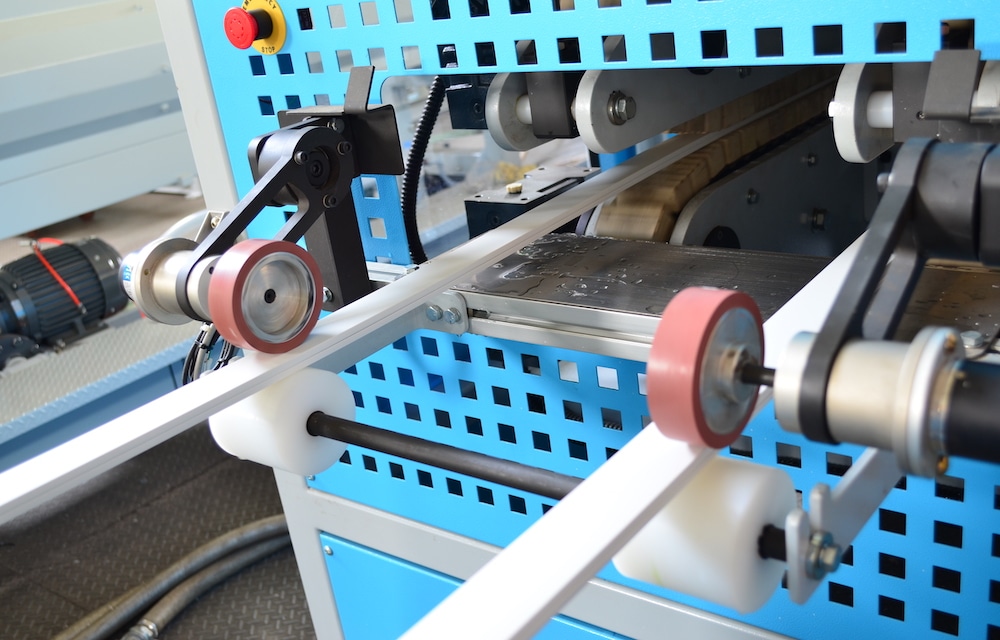

Everplast, a trusted manufacturer provides stable and durable extrusion machine lines. PVC trunking extrusion line uses a common die design and covers four trunking molds. It can produce two trunking products at once, efficiently saving material costs while achieving high efficiency, quality, and speed. The production efficiency and the design of the track allow customers to adjust the centrality according to the size of finished products.

Success story

PVC Trunking Machine Line

READ MORE…

Trunking Extrusion Machine Line

READ MORE…

Related Products

Profile Extrusion Machine Line

READ MORE...

Parallel Type Twin Screw Extruder Machine

READ MORE…

Send Products Inquiry to Us

To provide with better services, pleaser fill out the form below.