WPC Extrusion

Machine Line

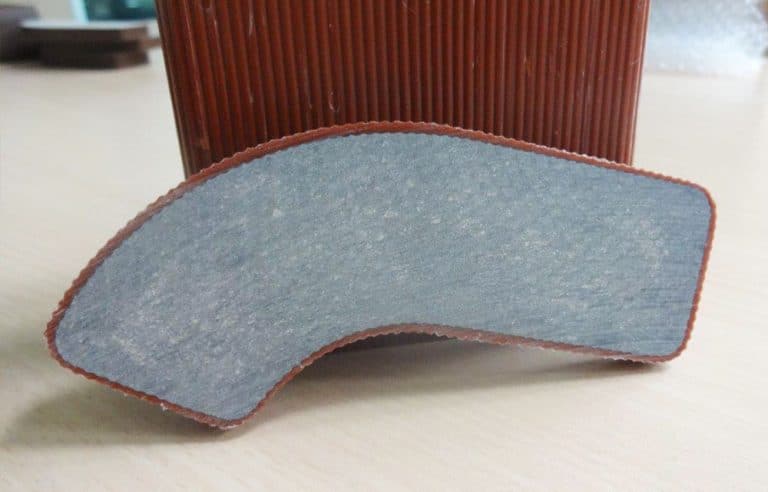

Our new generation high-level WPC Extrusion Machine Line can produce products close to real wood grain color as well as proceeding double layered co-extrusion at the same time. The wood products are more suitable for the outdoor climate and are slip-resistant. WPC products are currently applied in assembly of summer houses, roofing tiles, stairs, tables, and chairs, etc.

FEATURES

Using natural fiber in extruding profiles is getting popular. People try to develop new properties of the finished Wood Plastic Composite (WPC), such as PP/PE resin mixing 40-80% natural fiber or PVC mixing 40-70% natural fiber then produce different kinds of profiles.

According to the plastic substrate, WPC divides into PVC, PE, PP, PS, and ABS, and even products of PBT and PET are in development. Even though PVC is inflammable, it still has environmental protection issue. PE plastic wood has a large consumption; however, the oily wax texture of the material has low heat resistance, poor foaming, poor printing performance, and a product shrinkage; PP plastic wood has a wax texture and can withstand high temperature. Although the secondary processing has the risk of cracking, the appearance and texture are identical to a real wood, hence It can very well be done without post-production.

WPC extrusion machine line introduce

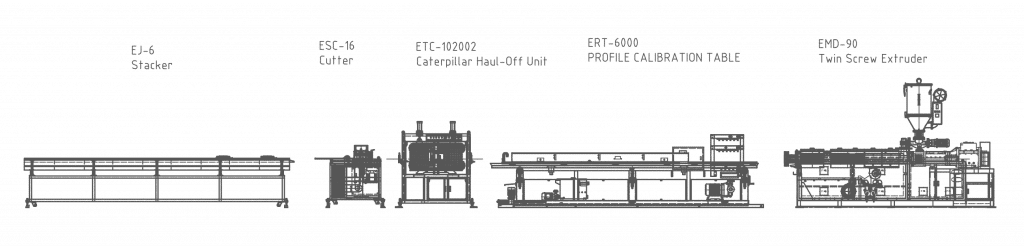

Based on this mass requirement, EVERPLAST MACHINERY has developed

1. segmented twin screw extruder + special single screw extruder line.

2. parallel twin screw extruder + special single screw extruder line combine tooling die head and all down stream equipments for WPC profiles production has already got very good result. We create the market for our customers come from all over the world.

APPLICATION

WPC divides into two parts: one being solid and the other being hollow. The inner surface of the hollow structure can produce a smooth and rough inner surface with the mold technology.

Our new generation high-level WPC extruder can produce products close to real wood grain color as well as proceeding double layered co-extrusion at the same time. The wood products are more suitable for the outdoor climate and are slip-resistant. WPC moulding products are currently applied in assembly of summer houses, roofing tiles, stairs, tables, and chairs, etc.

Plastic wood flooring is a new type of environmentally friendly and energy-saving composite material, a substitute for wood. Can be used for garden landscapes, interior and exterior wall decoration, flooring, barriers, flower ponds, gazebos, etc.! Waterproof and moisture proof. It fundamentally solves the problem that wood products are prone to decay and swelling after being damp and damp in humid and watery environments, and can be used in environments where traditional wood products cannot be used…

Send Products Inquiry to Us

To provide with better services, pleaser fill out the form below.